|

Low

Cycle Fatigue to

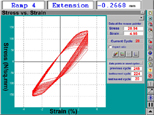

ASTM E466, E606 & BS 3518 gives fully flexible recording and display of

hysteresis loop

Low cycle fatigue

is associated with high strain fatigue where a fatigue cycle incorporates a

component of cyclic plastic strain.

Fatigue failure

generally occurs in a relatively small number of fatigue cycles, typically

a few thousands of cycles, compared with hundreds or thousands or millions

of cycles in normal fatigue failure.

The fatigue cycle

may be load, extension, stress or strain controlled or a mixture of these

modes. Frequently, dwell periods are incorporated as part of the fatigue

cycle and these may be from some seconds to many hours duration.

Cycle rates for low

cycle fatigue are normally less than 1 Hz. Low cycle fatigue is generally

conducted at elevated temperatures between 200°C to 1100°C.

Sophisticated data

capture techniques are required to minimise the quantity of data collected

whilst retaining the integrity of the test. Critical cycles are analysed to

determine stress and strain components.

The most common

specimens used in LCF testing are:

·

Hour glass

·

Parallel-sided, plain or ridged

·

Common cross-sections including: round or tubula

For further information, please click here.

|