|

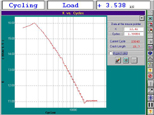

Automated

Precracking to

international Standards using a choice of compliance, potential drop or

manual techniques for automatic crack measurement

The purpose of

precracking is to introduce a defect into a specimen for subsequent

fracture toughness testing or crack growth investigation. In materials

testing, the defect takes the form of a small crack. Ideally, the crack

should have a sharp crack tip with minimal plastic zone surrounding the

crack front because any plasticity in front of the crack face will increase

resistance to crack growth. The ideal precrack can be achieved by:

·

initiating the crack at a high stress intensity factor (Kmax).

·

growing the crack whilst automatically reducing the stress

intensity factor (Kmax) by following a user programmed negative K gradient.

(This technique is also known as load shedding)

- finishing the crack growth

at a constant delta K until the desired crack length is achieved

For further information, please click here.

|